Plastic-type producing is becoming an essential part of numerous sectors. They have produced wonderful efforts to several career fields, for example auto, marine, agriculture, and others. With all the advancement in modern technology, distinct processes of plastic-type material production have emerged. Just about the most impressive and Rotational Molding sophisticated ones is rotomolding, that has transformed the plastics market. On this page, we shall investigate all that you should know about the rotomolding process.

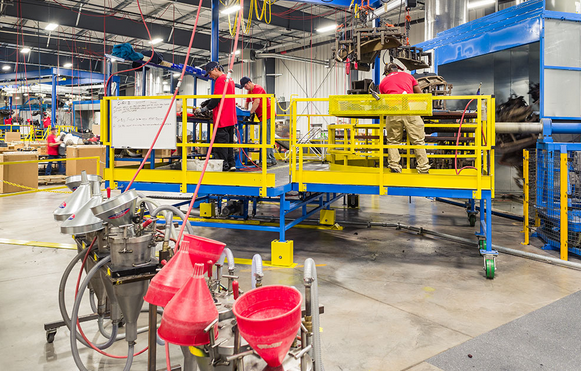

Rotomolding is an innovative technique utilized to create complicated plastic merchandise. It calls for molding the plastic by heating and turning it, letting it distributed evenly all over the mold work surface. This process is extremely accurate and makes high-quality items with incredible layout overall flexibility. Rotomolding is wonderful for making complicated shapes and elaborate types of plastic-type material products.

One important advantage of rotomolding is it can generate merchandise with easy, consistent surfaces. Consequently the products’ density and power are constant, which leads to great-high quality merchandise. An additional benefit of rotomolding is that it can create products of varied sizes and shapes, rendering it a well known option for different sectors.

Furthermore, rotomolding may use several types of thermoplastics. Polyethylene is regarded as the popular thermoplastic inside the rotomolding approach for its exceptional properties such as sturdiness, chemical level of resistance, and flexibility. Moreover, rotomolding is surroundings-helpful as it makes use of no solvents or paints to produce products.

Another considerable advantage of the rotomolding approach is its charge-effectiveness. In comparison to other plastic-type molding processes, the tooling and gear expense in rotomolding is fairly low. The simplicity of the procedure, consequently, cuts down on the production charges. This advantages causes it to be a well known option for small enterprises and begin-ups seeking to develop high-good quality plastic material goods.

Lastly, rotomolding also minimizes waste by assisting the reuse of your natural substance within the manufacturing procedure. As opposed to other molding operations, rotomolding can produce diverse merchandise from a single fungus, reducing the necessity for material change for each and every product. This lessens the spend generated through the manufacturing process.

In short:

In In short, rotomolding is really a innovative method that has significantly affected the plastic-type material producing business. It offers several benefits such as the capacity to develop intricate models, longevity and regularity, expense-efficiency, and environmental friendliness. As a result of these rewards, it has become a popular selection for producing plastic items across distinct market sectors. If you are contemplating production plastic-type material goods, rotomolding should be the ideal choice.